Peak to Peak

Helping industry access state-of-the-art measurement and monitoring technologies.

Who We Are

Peak to Peak Measurement Solutions Ltd. develop and supply advanced embedded sensor technologies. These measurement and monitoring technologies are deployed to key industrial sectors to support the transition to net-zero through advanced digitalisation.

Our micro-ultrasonic active transducers and monitoring systems are installed onto machines and processes to capture unique data streams about real-time system condition. Our tailored algorithms and on-the-edge processors convert this data to actionable insights.

Measurements

- Lubricant film thickness & degradation

- Lubricant/fluid viscosity

- Contact pressure, contact mapping, sealing, & interfacial stiffness

- Wear, corrosion, erosion, delamination

- Bulk material stress (static and dynamic), & residual stress

- Dynamic position & displacement

- Flash temperatures

Benefits

- Strategic maintenance

- Failure prevention

- Increased safety

- Increased efficiency

We work with industrial partners to help them access new technology to perform state-of-the-art measurements. Through collaboration with us, our partners understand more about their equipment, products, and assets resulting in improved functionality, cost reduction, and system optimisation.

To find out the different ways we work with collaborators, click here.

Our core sensor technologies

Active Ultrasonics

Acoustic Emissions

Temperature

Our complementary technologies

Strain Gauges

Vibration

Position

Pressure

Other/Bespoke

Measurements

We provide sensors and bespoke sensor systems to organisations worldwide for the following measurements.

Film Thickness

Contact Pressure

Wear

Viscosity

Stress

Acoustic Velocity

Attenuation

Bulk Modulus

Deflection

Density

Elastic Modulus

Geometry

Poissons's Ratio

Shear Stress

Industries we work in

Wheel and Rail

One of our favourite applications – the wheel-rail interface and vehicle-track interaction (VTI). We are the world leading experts in the following measurements:

- Wheel-rail contact patch size, location, and pressure, yaw, wheelflats

- Wheel-rail interfacial stiffness, from which rail roughness and traction can be monitored

- Lubricant and other 3rd body layer (leaves, sand, water, ice) condition/thickness

- Dynamic stress (L/V), residual stress, longitudinal rail stress

Manufacturing

Many manufacturing operations rely on precise control of high pressure tolling interfaces. To optimise productivity and quality, these interfaces can be monitored to ensure optimum conditions. Some examples include:

- Metal extrusion/punching tool-die interface contact pressure, area, and tool wear.

- Steel rolling – contact pressure and area, lubricant film thickness, stress.

Propulsion

We have instrumented and tested many small, mid-size, and large combustion engine components for in situ measurement and monitoring of:

- Main and journal bearing lubricant film thickness and viscosity

- Bearing wear

- Piston-ring & liner lubricant film thickness

- Liner dynamic stress, internal flash temperature, and wear

Marine

We focus on 2 distinct applications in the marine market:

- Combustion engine journal bearing and piston-liner film thickness, dynamic piston stress, flash temperatures, and liner wear

- Environmentally acceptable lubricants – performance characterisation concerning high shear rates, pressure-viscosity effects, and degradation/hydrolysis

Wind Turbines

We predominantly focus our wind turbine efforts on the measurement and monitoring of main, pitch, and gearbox bearings. The following parameters are reported:

- Roller & race contact size, pressure, location, skew, and misalignment.

- Trapped and free-surface lubricant film thickness and reflow rate.

- Race wear and stratic/dynamic stresses.

How We Work

Peak to Peak works with small and large industrial and academic partners worldwide. We provide specialist knowledge and bespoke equipment solutions to help our collaborators measure and monitor the key parameters of their equipment. Some example collaborative frameworks are described below, for more specific examples have a look at our Case Studies

Consultancy

We provide expert advice about the most appropriate sensor systems that are available and provide support in procurement, installation, and data treatment. We also have a wide area of expertise in the fields of tribology, lubricants, and rotating machines.

Often, the best place to start is a small consultancy collaborative project to give first-hand experience of the instrumentation options moving forward.

Testing in our labs

We have a wide range of measurement equipment and benchtop demonstration testing platforms, where we can demonstrate different measurement capabilities or perform rigorous product testing on your behalf.

Our labs are constantly growing and we have a wide range of trusted industrial partnerships, so get in touch and we can let you know if we can carry any testing burdens you may be having.

Installation and testing/monitoring in your facility

We can provide bespoke instrumentation of your components with a wide range of sensor technologies and our expert team members can travel to your location, help with the installation, set-up of the equipment and any integration/IoT.

From there, either we can operate the data capture equipment and provide the results to you in a report, or we can permanently supply you with the equipment and provide training so you have the in-house capabilities to perform ongoing testing/condition monitoring.

In-service field measurements

We have a breadth of experience instrumenting field equipment. We can work with your team to plan the most appropriate instrumentation program and then we can either instrument the equipment in advance and travel on-site to support with the set-up, or in many cases, we can provide the installation on-site, there and then.

This can be a one-off test or we can permanently supply the equipment for continuous condition monitoring. We can also help with data handling, cloud-based data access, machine learning/ANN, and integration to your systems.

Supply of serial measurement product

We can work with your team to develop a serial sensor solution that OEMs and other industrial organisations can then supply as an increased value product offering to your customers.

“What about all the data?”

Some of our customers want to work with us to develop their own data treatment algorithms and to keep this internal. Others prefer us to configure the system to provide real-time output of whatever the parameter is that is required.

Our technology in action

See below for some example products we have delivered to our industrial partners.

Under-Rail Sensor for Vehicle-Track Interaction Condition Monitoring

Industries

Wheel/Rail

Measurements

- h Film Thickness

- p Contact Pressure

- w Wear

- σ Stress

- Temperature

Technologies

- Position

- Acoustic Emissions

- Thermocouples

- Active Ultrasonics

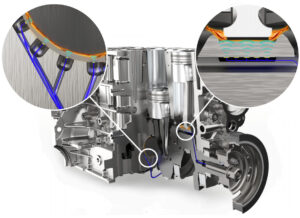

Embedded engine sensors for main and big end bearing oil film thickness monitoring

Industries

Automotive

Measurements

- h Film Thickness

- σ Stress

- Temperature

Technologies

- Position

- Thermocouples

- Active Ultrasonics

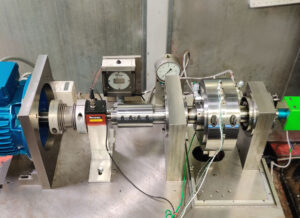

Hydrodynamic lubricant characterisation using advanced sensor ensemble

Industries

Marine, Automotive, Lubrication

Measurements

- h Film Thickness

- η Viscosity

- σ Stress

- Film Breakdown

- Pressure

- Scuffing

- Temperature

- Vibration

Technologies

- Position

- Acoustic Emissions

- Thermocouples

- Active Ultrasonics

Instrumented engine liner for piston-ring oil film thickness measurement

Industries

Automotive

Measurements

- h Film Thickness

- σ Stress

- Temperature

Technologies

- Position

- Thermocouples

- Active Ultrasonics

Contact

Please feel free to use this form to get in touch with us with any queries, we are always excited to hear about new instrumentation and measurement challenges, alternatively drop us an email at [email protected] and we will get straight back to you.